500KV Power Transformer

We will send the quotation to you within 24 hours.

500KV Power Transformer

Technical parameters and features

1.Low Loss and Low Noise

The core disc takes the high performance silicon steel sheet and the laminated type of the five-level step full oblique joint, which can provide the low no-load loss and noise. The oil tank takes the combined shielding technology of the magnetic shielding and the copper shielding, and the core structure part takes the measure to reduce the eddy current loss according to different positions in the leakage magnetic field, which reduces the load loss and solve the local over-temperature of the transformer radically.

2.Safe and Reliable Operation

Our company always pays more attention to the reliability of products, and the insulation design of the transformer reserves relative margin. The local discharge capacity of products is maintained under 100pC, to ensure the stable operation of the transformer under the long-term operating voltage and the short-term voltage. In order to extend the service life of the transformer and improve the short circuit withstand capability, the cooling structure is designed rationally and the temperature rise of the transformer winding and the temperature rise of the oil surface is lower than the national standard for 5K. When the transformer is short circuit, the mechanical stress of the winding lead is low, and it combines with other short circuit withstand measure and strict production process guarantee. The 400kV and 500kV transformer of our company can undertake the examination under various conditions completely.

3. Powerful Name Plate Operating Capacity and Excellent Thermal Performance

At present, the oil-immersed power transformer usually controls the operation of the transformer with load by limiting the average temperature rise of the winding, to implement the thermal service life of the transformer. During the research and development, the control of the hot spot temperature is more important than the control of the average temperature for the ultrahigh voltage transformer with large capacity. For the transformer with the natural oil circulation, it is possible that the average temperature rise of the oil complies with the requirement, while the temperature rise of the hot spot exceeds its limit. Hence, it is necessary to detailed calculate and strictly control the hot spot temperature rise of the large-capacity transformer.

4. Convenient to Install and maintain

To reduce the workload for the site installation and ensure the smooth installation, it is not necessary to check the hang cover during the site installation, and all accessories are preloaded before the delivery. The secondary cable is deployed to the transformer main body before the delivery and led to the terminal box and the control box. Most of the 400kV and 500kV power transformer designed and manufactured by our company takes the natural oil circulation and air cooling and can provide 70% of the cooling capacity when the fan terminates. Hence, it is not necessary to maintain the cooling system.

5.Elaborate Operation

Make the winding by the tension device of the vertical coil winding machine, to reduce the winding margin, ensure the radial tension force of all windings, and improve the strength of the winding itself. Combine with the assembly process before the overall installation of the winding, to reduce the assemble tolerance of the transformer body and improve the overall strength of the transformer body. All of the force insulated parts are composed of the special hard cardboard, such as the winding block, to reduce the shrinkage of the insulated part. Upon completion of the winding, it will be stabilized by the kerosene vapor phase drying technology, and it will be carried out with the kerosene vapor phase drying for one time after the assembly of the transformer body, to ensure the insulation of various parts is reduced and the insulated parts is not reduced during the operation. All high voltage electrodes and metal structure parts are rounded, to prevent the point discharge. The voltage equalizing ball for the high voltage bushing goes into the ascending flanged base, to ensure the voltage equalizing ball is in the even electric field. The lead takes the cold pressure welding, and implements the shield processing for the rounding. It reduces the water content of the insulated parts and improves the cleanliness of the transformer body after the transformer body is dried by the large-sized kerosene vapor phase drying equipment. The oil tank is reshaped and relieves the stress after the welding of the oil tank, and implements the integral sand blasting, to ensure the appearance cleanliness of the transformer, and there is not any leakage.

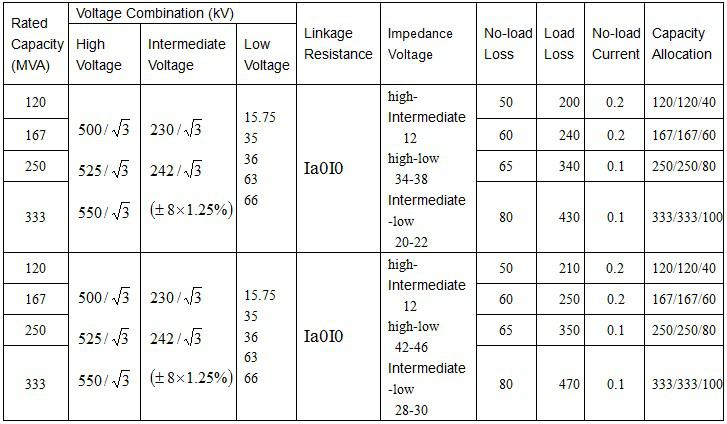

Technical Parameters of 500kV Single Phase Self-coupling Three Winding Load Voltage Regulating Transformer

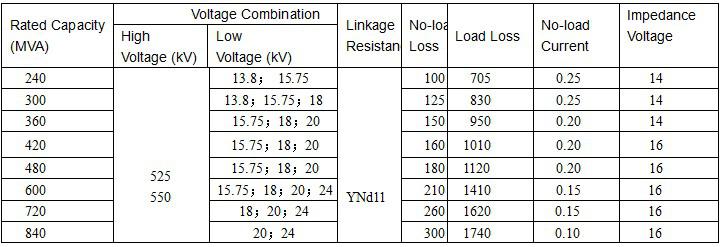

Technical Parameters of 500Kv Three-phase Dual Winding Transformer

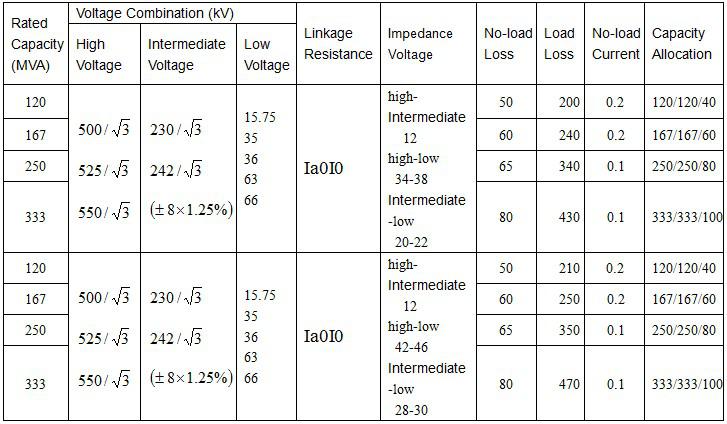

Technical Parameters of 500Kv Single-phase Three Winding Voltage Regulating Transformer without Excitation

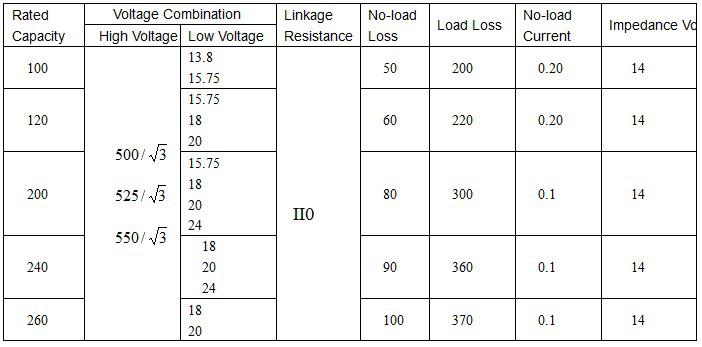

Technical Parameters of 500Kv Single-phase Dual Winding Transformer

- 110KV power transformer 220kv power transformer 330KV power transformer 35KV power transformer 500KV power transformer

English

English 简体中文

简体中文 Isolating Contact

Isolating Contact  Loop Resistance Tester

Loop Resistance Tester  Tripping Shaft

Tripping Shaft